MANUFACTURING EXCELLENCE

HANDCRAFTED WITH PASSION

Each APEX tent is handcrafted with dedication and pride.

From concept to completion, our tents are not just manufactured —

they are thoughtfully created. Every stitch, every cut of canvas,

and every welded steel frame reflects commitment to craftsmanship.

These are functional works art built with passion and care.

CRAFTED IN TAMIL NADU

All our tents are designed and handcrafted in Tamil Nadu

by highly skilled craftsmen women. Their expertise, precision

and attention detail bring every structure life.

Our creations now travel Kerala, Goa, Himalayas, Maldives,

Sri Lanka beyond — quietly beautifying landscapes world.

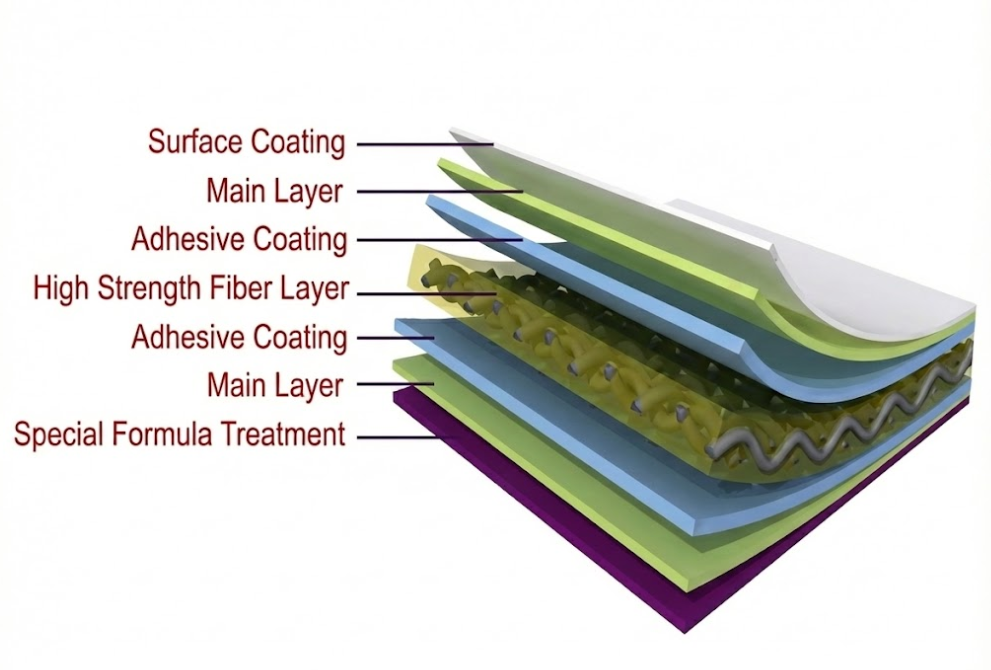

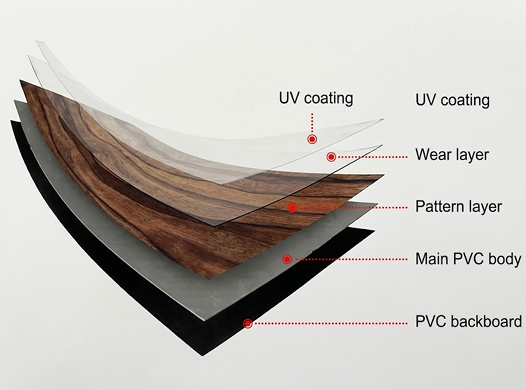

UNCOMPROMISING ATTENTION TO DETAIL

We believe small details make biggest difference.

Extra time invested at every stage manufacturing.

Any imperfection identified during quality control

and corrected immediately.

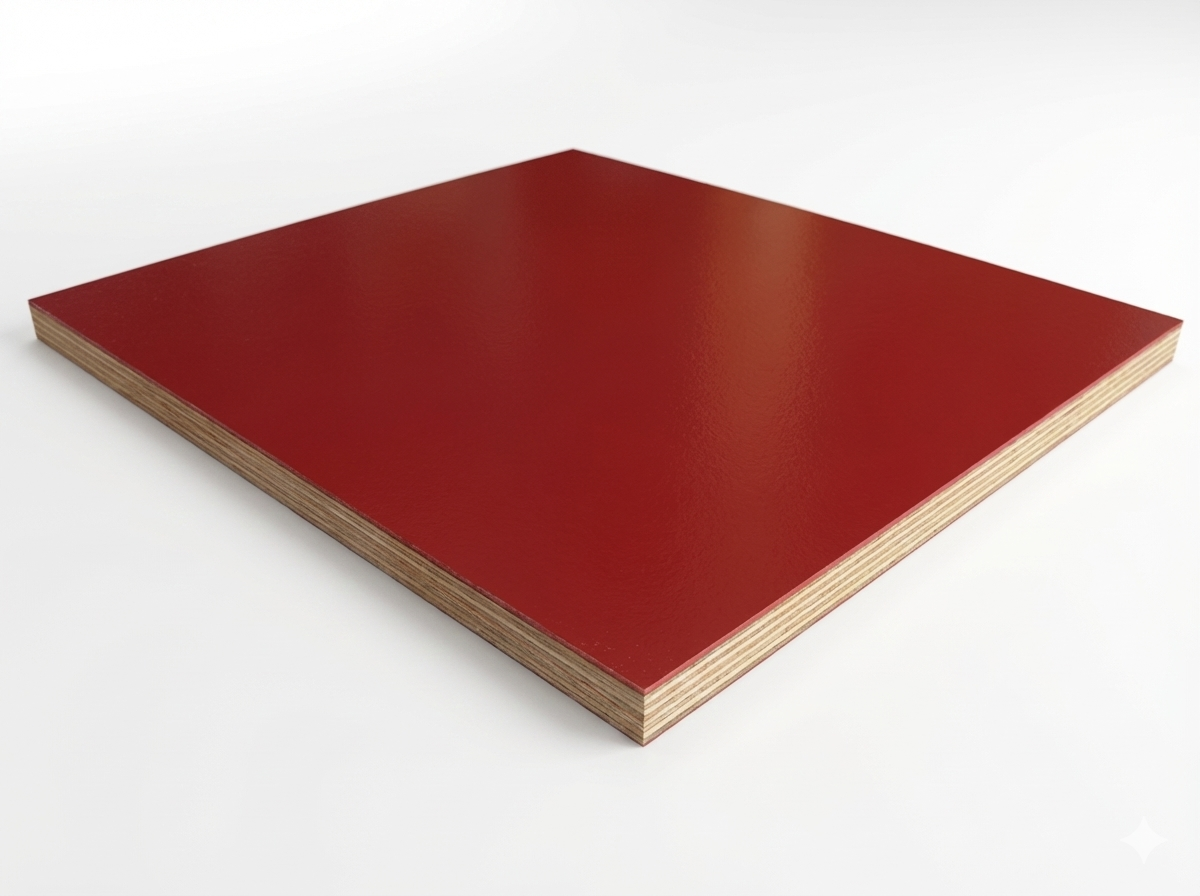

QUALITY CHECKED. THEN CHECKED AGAIN.

Before any tent leaves facility, it is fully assembled

and inspected multiple times. Our goal simple:

when your tent arrives, it should be nothing short perfect.